Contact us now and you'll hear back from us in less than 90 minutes, our promise!

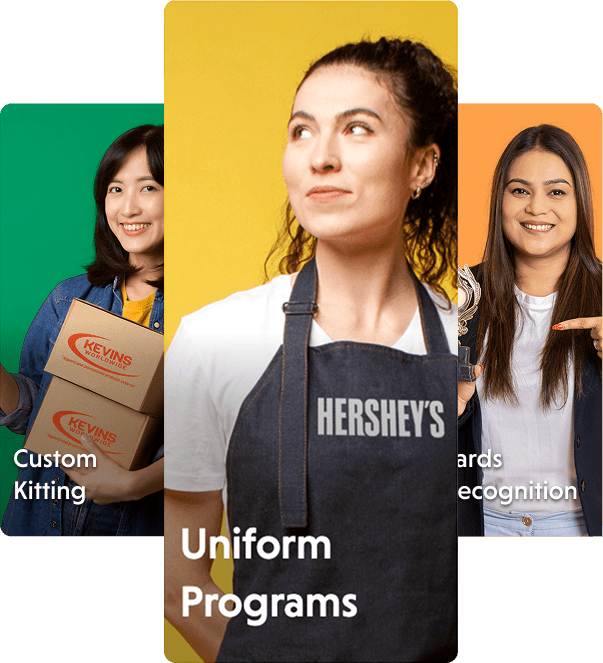

One of America’s largest providers for Uniform Programs, Incentives, and Swag Stores since 1994!

Managed Uniform Programs

If your company uses branded apparel you already know the headache of keeping everyone outfitted. Managed uniform programs handle the sourcing, ordering, inventory, and distribution.

Managed Uniform Programs

If your company uses branded apparel you already know the headache of keeping everyone outfitted. Managed uniform programs handle the sourcing, ordering, inventory, and distribution.

What Managed Uniform Programs Are and Why Your Business Should Care

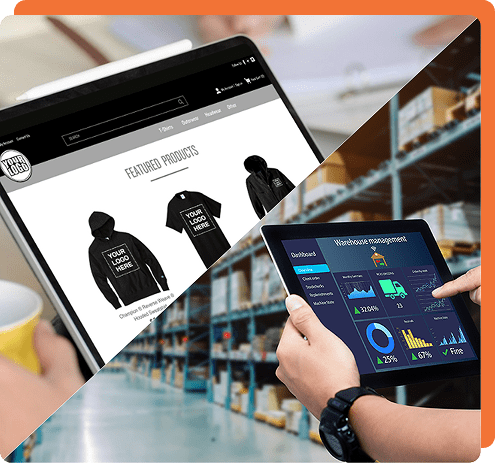

One partner sourcing your branded apparel, decorating it with your logo, tracking inventory, and getting it to your employees when they need it – on an ongoing basis.

The Basics of Uniform Management

Managed programs streamline sourcing, decorating, and distribution of branded apparel. Set standards once—approved items, logos, and ordering rules—for consistent uniforms company-wide. Consolidate swag fulfillment and uniforms to simplify operations and reduce vendor juggling.

What This Solves for Your Company

A managed program eliminates the chaos of outfitting teams. It centralizes ordering, enforces budgets, supports all sizes, ensures brand and safety compliance, and gives full visibility into usage—saving admin time while keeping every employee consistently on-brand.

Where the Cost Savings Come From

What Happens When You Launch Uniform

Uniform Programs

3 phases. Here’s what happens at each stage:

1. Program Setup and Design

Your partner defines needs, selects products, sets decoration standards, and gets your pre-production approval—ensuring every uniform fits your budget, brand, and performance requirements before rollout.

2. How Inventory and Distribution Work

Core items are warehoused and shipped on demand. Seasonal or specialty gear is ordered as needed, with flexible distribution—bulk or direct-to-employee—based on your company’s setup.

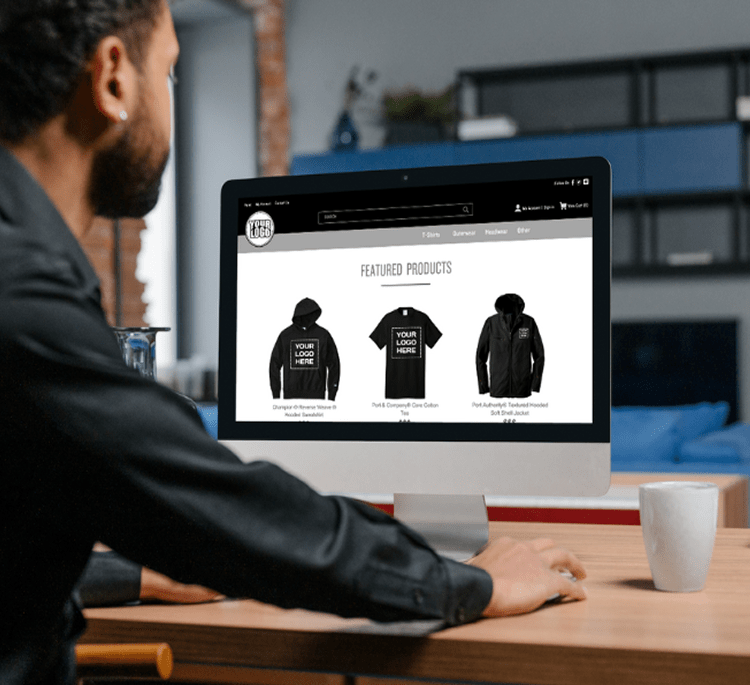

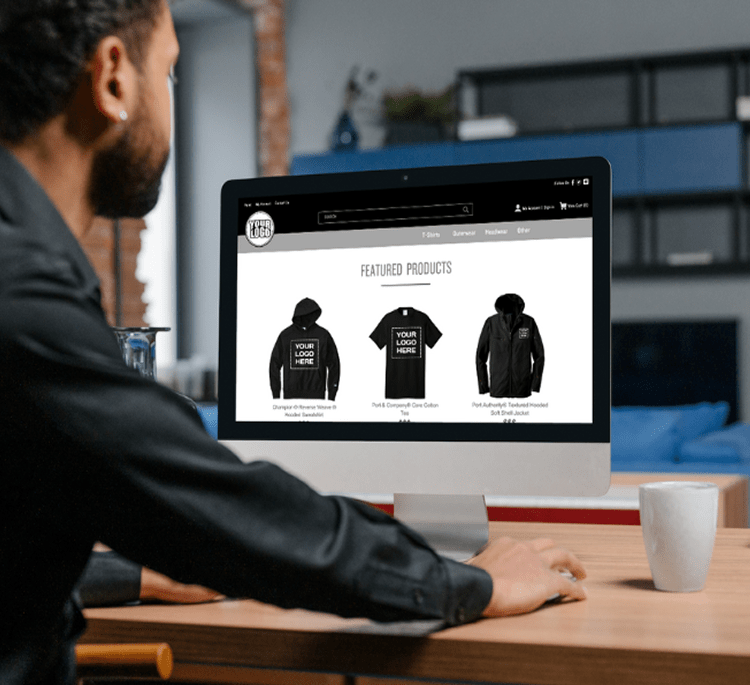

3. The Uniform Ordering Process

Employees order through secure portals with built-in approval rules and spending limits. The system automates tracking, reporting, and budgeting—keeping orders compliant, transparent, and efficient.

What Happens When You Launch Uniform

Uniform Programs

3 phases. Here’s what happens at each stage:

1. Program Setup and Design

Your partner defines needs, selects products, sets decoration standards, and gets your pre-production approval—ensuring every uniform fits your budget, brand, and performance requirements before rollout.

2. How Inventory and Distribution Work

Core items are warehoused and shipped on demand. Seasonal or specialty gear is ordered as needed, with flexible distribution—bulk or direct-to-employee—based on your company’s setup.

3. The Uniform Ordering Process

Employees order through secure portals with built-in approval rules and spending limits. The system automates tracking, reporting, and budgeting—keeping orders compliant, transparent, and efficient.

What Happens When You Launch

Uniform Programs

3 phases. Here’s what happens at each stage:

1. Program Setup and Design

Your partner defines needs, selects products, sets decoration standards, and gets your pre-production approval—ensuring every uniform fits your budget, brand, and performance requirements before rollout.

2. How Inventory and Distribution Work

Core items are warehoused and shipped on demand. Seasonal or specialty gear is ordered as needed, with flexible distribution—bulk or direct-to-employee—based on your company’s setup.

3. The Uniform Ordering Process

Employees order through secure portals with built-in approval rules and spending limits. The system automates tracking, reporting, and budgeting—keeping orders compliant, transparent, and efficient.

Choosing a Managed Uniform Provider

Service and Support

Dedicated teams know your brand, handle rush orders efficiently, and communicate clearly to keep every request running smoothly.

What to Look For in a Provider

Choose one with in-house decoration, warehousing, and intuitive software to streamline orders, tracking, and overall program management.

Pricing Models

Compare total program costs, not just item prices—factor setup fees, add-ons, and time saved managing vendors.

Choosing a Managed Uniform Provider

Service and Support

Dedicated teams know your brand, handle rush orders efficiently, and communicate clearly to keep every request running smoothly.

What to Look For in a Provider

Choose one with in-house decoration, warehousing, and intuitive software to streamline orders, tracking, and overall program management.

Pricing Models

Compare total program costs, not just item prices—factor setup fees, add-ons, and time saved managing vendors.

Over 30 Years Managing Employee Uniform Programs

Embroidery

Screen Printing

Fulfillment

Online ordering

Testimonials

Frequently Asked Questions

What does a managed uniform program include?

A managed uniform program includes sourcing branded apparel, decorating it with your logo through embroidery or screen printing, warehousing inventory, and distributing it to employees through online ordering portals or direct shipments. The partner handles approval workflows, spending limits, and reporting so you’re not managing logistics yourself.

How do managed uniform programs reduce costs?

Managed uniform programs reduce costs by consolidating orders with one partner for better pricing, eliminating rush fees through proper inventory management, and cutting administrative time spent coordinating with multiple vendors. You also avoid over-ordering or emergency purchases because the partner tracks usage and restocks based on what you’re going through.

Which industries use managed uniform programs?

Industries like manufacturing, construction, hospitality, and food service use managed uniform programs because their teams need consistent branded apparel that meets job-specific requirements. Companies with 500+ employees across multiple locations get the most benefit from centralized ordering, inventory tracking, and approval systems.

Can uniform programs include recognition or milestone items?

Uniform programs can include recognition elements like embroidered tenure patches, anniversary jackets, or milestone gear when the partner handles decorated apparel. This keeps all your employee apparel—daily uniforms and special recognition items—under one program with consistent branding and decoration standards.

When should a company start a managed uniform program?

A company should start a managed uniform program when juggling multiple vendors creates brand inconsistencies, budget unpredictability, or administrative burden for HR and operations teams. Programs work best for businesses spending at least $20,000 annually on branded apparel across multiple locations or departments.

Why choose a partner with in-house decoration capabilities?

Partners with in-house embroidery and screen printing offer faster turnarounds and better quality control than those who outsource decoration to other vendors. You get more flexibility for custom workwear, specialty items, and rush orders because everything happens under one roof.

What does a managed uniform program include?

A managed uniform program includes sourcing branded apparel, decorating it with your logo through embroidery or screen printing, warehousing inventory, and distributing it to employees through online ordering portals or direct shipments. The partner handles approval workflows, spending limits, and reporting so you’re not managing logistics yourself.

How do managed uniform programs reduce costs?

Managed uniform programs reduce costs by consolidating orders with one partner for better pricing, eliminating rush fees through proper inventory management, and cutting administrative time spent coordinating with multiple vendors. You also avoid over-ordering or emergency purchases because the partner tracks usage and restocks based on what you’re going through.

Which industries use managed uniform programs?

Industries like manufacturing, construction, hospitality, and food service use managed uniform programs because their teams need consistent branded apparel that meets job-specific requirements. Companies with 500+ employees across multiple locations get the most benefit from centralized ordering, inventory tracking, and approval systems.

Can uniform programs include recognition or milestone items?

Uniform programs can include recognition elements like embroidered tenure patches, anniversary jackets, or milestone gear when the partner handles decorated apparel. This keeps all your employee apparel—daily uniforms and special recognition items—under one program with consistent branding and decoration standards.

When should a company start a managed uniform program?

A company should start a managed uniform program when juggling multiple vendors creates brand inconsistencies, budget unpredictability, or administrative burden for HR and operations teams. Programs work best for businesses spending at least $20,000 annually on branded apparel across multiple locations or departments.

Why choose a partner with in-house decoration capabilities?

Partners with in-house embroidery and screen printing offer faster turnarounds and better quality control than those who outsource decoration to other vendors. You get more flexibility for custom workwear, specialty items, and rush orders because everything happens under one roof.